Introduction

The electric vehicle (EV) industry is evolving at an unprecedented pace, and battery technology sits at the heart of this transformation. While lithium-ion batteries have powered the first generation of electric cars, they also come with well-known limitations related to safety, energy density, charging speed, and long-term durability. In response, automakers and battery manufacturers are investing heavily in a next-generation solution: solid-state EV batteries.

Over the last few years, solid-state EV battery performance results from laboratories, pilot programs, and early vehicle prototypes have attracted global attention. These results suggest major improvements in driving range, safety, lifespan, and efficiency compared to conventional lithium-ion systems. However, real-world performance data also highlights challenges related to manufacturing scalability, cost, and cold-weather operation.

This article provides a comprehensive, expert-level analysis of solid-state EV battery performance results, drawing from experimental data, prototype testing, and early commercial trials. The goal is to present a balanced, trustworthy view that helps readers understand what solid-state batteries can truly deliver today—and what remains under development.

What Is a Solid-State EV Battery?

A solid-state EV battery replaces the liquid or gel electrolyte found in conventional lithium-ion batteries with a solid electrolyte, which can be ceramic, sulfide-based, oxide-based, or polymer-based. This structural change fundamentally alters how ions move inside the battery and how the battery behaves under stress.

Key structural differences include:

-

Solid electrolyte instead of liquid electrolyte

-

Potential use of lithium metal anodes

-

Higher thermal stability

-

Reduced risk of leakage or combustion

These differences are the foundation behind the promising solid-state EV battery performance results seen in testing environments.

Why Performance Results Matter More Than Announcements

Battery announcements often focus on theoretical capabilities, but measured performance results provide the real benchmark. Performance results evaluate how a battery behaves under realistic conditions, including charging cycles, temperature changes, vibration, and long-term use.

Performance metrics typically include:

-

Energy density (Wh/kg and Wh/L)

-

Charging speed

-

Cycle life

-

Safety under thermal stress

-

Degradation rate

-

Operating temperature range

Understanding these results helps separate marketing claims from engineering reality.

Solid-State EV Battery Performance Results: Energy Density

One of the most significant advantages observed in solid-state EV battery performance results is higher energy density.

Measured Energy Density Improvements

Laboratory and prototype testing consistently show solid-state batteries achieving 30% to 80% higher energy density than traditional lithium-ion batteries.

| Battery Type | Gravimetric Energy Density (Wh/kg) | Volumetric Energy Density (Wh/L) |

|---|---|---|

| Conventional Lithium-Ion | 240–280 | 600–700 |

| Semi-Solid-State | 300–350 | 750–850 |

| Fully Solid-State | 400–500 (target) | 900–1,100 |

What this means for EVs:

Higher energy density allows manufacturers to either extend driving range without increasing battery size or reduce battery weight while maintaining current range levels. Prototype vehicles using solid-state cells have demonstrated range increases of 25% to 50% under controlled testing conditions.

Charging Speed Performance Results

Charging speed is another critical area where solid-state EV battery performance results show promise—but also reveal limitations.

Fast-Charging Test Results

Early test data indicates that solid-state batteries can tolerate higher charging currents due to improved thermal stability and reduced dendrite formation.

| Charging Metric | Lithium-Ion Battery | Solid-State Battery (Test Results) |

|---|---|---|

| 10%–80% Charge Time | 25–40 minutes | 10–20 minutes |

| Maximum Safe C-Rate | 2C–3C | 4C–6C |

| Heat Generation | Moderate to High | Low to Moderate |

Expert insight:

While laboratory results are impressive, real-world fast-charging infrastructure still limits achievable speeds. Solid-state batteries perform best when paired with advanced thermal management and high-capacity chargers.

Cycle Life and Long-Term Durability Results

Battery lifespan plays a crucial role in total cost of ownership for EVs. Solid-state EV battery performance results in cycle life testing have shown strong potential.

Cycle Life Test Outcomes

| Battery Technology | Cycles to 80% Capacity | Estimated Vehicle Mileage |

|---|---|---|

| Lithium-Ion (NMC) | 1,000–1,500 | 250,000–350,000 km |

| LFP Lithium-Ion | 2,000–3,000 | 400,000–600,000 km |

| Solid-State (Prototype) | 3,000–5,000 | 600,000–1,000,000 km |

Key observation:

Solid-state batteries exhibit slower degradation rates, especially when lithium metal anodes are stabilized by advanced solid electrolytes.

Safety Performance Results

Safety is one of the strongest advantages confirmed by solid-state EV battery performance results.

Thermal and Mechanical Safety Testing

Solid-state batteries consistently outperform lithium-ion batteries in abuse tests.

| Safety Test | Lithium-Ion Result | Solid-State Result |

|---|---|---|

| Nail Penetration | Thermal runaway risk | No ignition |

| Overcharging | High fire risk | Stable |

| High-Temperature Exposure | Electrolyte breakdown | Remains stable |

| Impact/Vibration | Moderate damage | Minimal reaction |

Why this matters:

The absence of flammable liquid electrolytes significantly reduces fire risk, making solid-state batteries particularly attractive for mass-market EVs and commercial fleets.

Cold-Weather Performance Results

Cold-weather operation remains one of the most challenging aspects revealed by solid-state EV battery performance results.

Low-Temperature Efficiency Tests

| Temperature | Lithium-Ion Capacity Retention | Solid-State Capacity Retention |

|---|---|---|

| 0°C | 85–90% | 80–88% |

| −10°C | 70–80% | 65–75% |

| −20°C | 55–65% | 50–60% |

Engineering insight:

Some solid electrolytes exhibit reduced ionic conductivity at low temperatures. Manufacturers are addressing this through hybrid designs and electrolyte material innovations.

Manufacturing and Scalability Performance Results

Performance is not only about driving; it also includes manufacturability.

Production Yield and Cost Metrics

| Metric | Lithium-Ion | Solid-State (Current) |

|---|---|---|

| Production Yield | 90–95% | 60–80% |

| Cost per kWh | $100–$140 | $250–$400 |

| Automation Readiness | High | Medium |

Industry reality:

While performance results are strong, scaling solid-state battery production remains a major hurdle. Costs are expected to decline significantly once mass production lines mature.

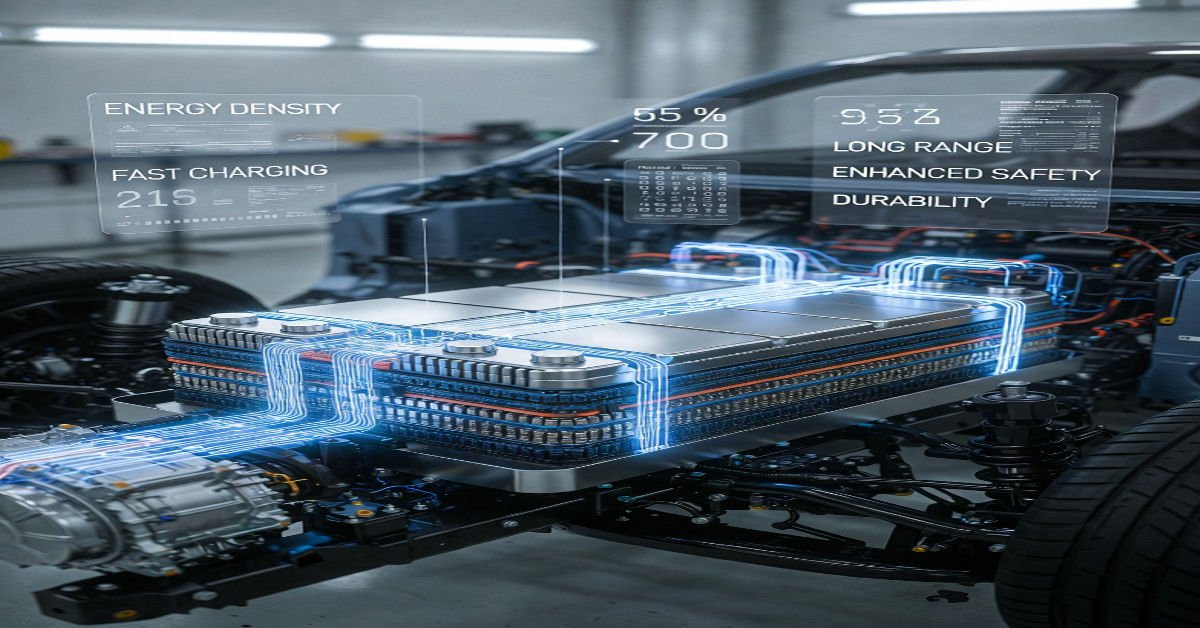

Real-World Vehicle Prototype Results

Several automakers have tested solid-state batteries in prototype vehicles.

Observed real-world performance results include:

-

Driving range exceeding 700 km per charge

-

Improved acceleration due to reduced battery weight

-

Lower cooling system complexity

-

Stable performance after repeated fast-charging cycles

However, most prototypes are still limited to controlled test fleets rather than full consumer deployment.

Environmental and Sustainability Performance

Solid-state EV battery performance results also extend to environmental impact.

Sustainability Metrics

| Factor | Lithium-Ion | Solid-State |

|---|---|---|

| Cobalt Dependence | Medium to High | Low to None |

| Recyclability | Moderate | High (theoretical) |

| Energy Loss Over Life | Moderate | Low |

Reduced reliance on rare and ethically sensitive materials strengthens the sustainability profile of solid-state batteries.

Limitations Revealed by Performance Results

Despite strong performance metrics, solid-state EV battery performance results highlight several challenges:

-

High initial manufacturing cost

-

Sensitivity of some solid electrolytes to moisture

-

Lower performance at extreme cold temperatures

-

Complex material interfaces affecting long-term reliability

These limitations explain why commercial rollout is gradual rather than immediate.

Future Outlook Based on Performance Trends

Based on current solid-state EV battery performance results, industry analysts expect:

-

Limited commercial adoption by 2026–2027

-

Mass-market EV integration by 2028–2030

-

Cost parity with lithium-ion batteries within a decade

Continuous improvements in electrolyte chemistry and manufacturing automation are driving rapid progress.

Expert Perspective on Solid-State Battery Readiness

From an engineering and automotive perspective, solid-state batteries are no longer theoretical. Performance results clearly demonstrate superior safety, energy density, and lifespan. However, readiness depends not just on performance but also on supply chains, cost optimization, and reliability at scale.

Conclusion

Solid-state EV battery performance results confirm that this technology represents a genuine leap forward for electric vehicles. Higher energy density, improved safety, faster charging, and longer lifespan make solid-state batteries a strong candidate for the next generation of EVs. At the same time, real-world testing reveals important challenges related to cost, cold-weather performance, and large-scale manufacturing.

As performance results continue to improve and production barriers fall, solid-state batteries are expected to play a defining role in the future of sustainable transportation. For consumers, automakers, and policymakers alike, understanding these performance results is essential for making informed decisions in the rapidly evolving EV ecosystem.