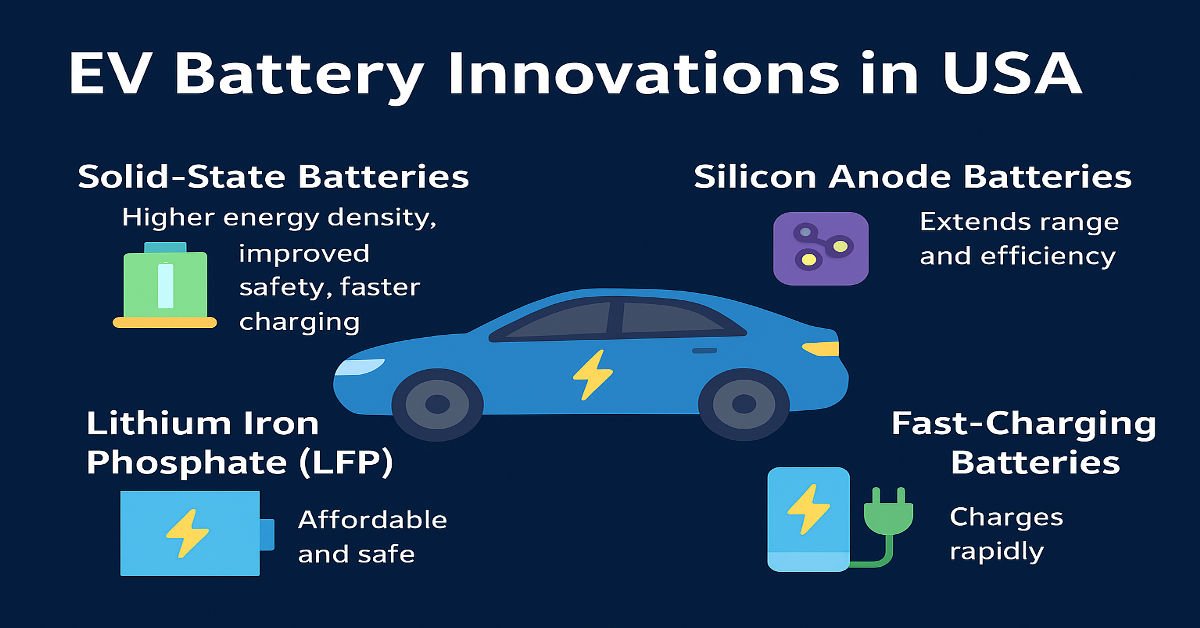

EV Battery Innovations in USA are reshaping the transportation industry in the United States. At the core of this transformation lies a technological revolution — EV battery innovation. Over the last few years, U.S. automakers, tech startups, and research institutions have made groundbreaking progress in developing advanced, efficient, and sustainable battery technologies. These innovations are not only extending driving ranges and improving charging times but are also redefining how clean mobility can be achieved.

Understanding the Importance of EV Battery Technology

Batteries are the heart of an electric vehicle. They determine not only how far the car can travel but also how fast it can recharge, how long it lasts, and how environmentally friendly it is. The performance of EV batteries influences the adoption rate of electric vehicles across the country.

Currently, lithium-ion batteries dominate the EV market. However, U.S. researchers and automakers are experimenting with new materials and designs to create the next generation of batteries that can charge faster, cost less, and last longer. These include solid-state batteries, silicon anodes, lithium-sulfur, and recyclable battery chemistries.

Evolution of EV Batteries in the United States

To understand how innovations are reshaping EV batteries, it helps to look back at how this technology has evolved:

| Battery Generation | Time Period | Key Innovation | Impact on EVs |

|---|---|---|---|

| 1st Generation | 2000–2010 | Nickel-Metal Hydride (NiMH) | Used in early hybrids like the Toyota Prius |

| 2nd Generation | 2010–2020 | Lithium-Ion Batteries | Became standard for EVs with improved energy density |

| 3rd Generation | 2020–2025 | Advanced Li-ion, LFP, Solid-State Prototypes | Higher range, faster charging, improved safety |

| 4th Generation | 2025 onward | Solid-State, Sodium-Ion, and Silicon-Based | Next-gen batteries with ultra-fast charging and long lifespan |

Each generation marks a major improvement in energy density, safety, cost, and sustainability, driving EV adoption across the U.S.

Major Areas of EV Battery Innovation in the USA

Let’s explore the most important areas of innovation that are shaping the future of electric vehicles.

1. Solid-State Batteries: The Future of EV Power

One of the most anticipated advancements in EV battery technology is the solid-state battery. Unlike traditional lithium-ion batteries that use liquid electrolytes, solid-state batteries employ solid electrolytes. This change offers several advantages:

-

Higher energy density – They can store more energy in the same space.

-

Improved safety – Solid electrolytes are non-flammable.

-

Longer lifespan – Reduced degradation over time.

-

Faster charging – Potential to recharge up to 80% in under 15 minutes.

Several U.S. companies and research institutions are leading this field. QuantumScape, based in California, has developed prototype solid-state batteries that can outperform conventional lithium-ion cells. Toyota, Ford, and General Motors are also collaborating with U.S. tech firms to bring solid-state batteries to mass production by 2027–2028.

| Company | Innovation | Key Benefit |

|---|---|---|

| QuantumScape | Solid ceramic electrolyte | 80% charge in 15 minutes |

| Ford Motor Co. | Solid-state R&D partnership | 50% higher energy density |

| GM & Solid Power | Sulfide-based solid electrolyte | Safer and faster charging |

These developments promise to make EVs lighter, safer, and more efficient.

2. Silicon Anode Batteries: Extending Range and Efficiency

Traditional lithium-ion batteries use graphite anodes. However, replacing graphite with silicon can increase energy storage capacity by up to 30–40%. Silicon anodes can hold more lithium ions, thereby extending vehicle range without increasing battery size.

Sila Nanotechnologies, a California-based company, is leading this innovation. It has developed a silicon-dominant anode material that will be used in upcoming EV models from Mercedes-Benz and BMW. Sila’s approach focuses on nano-engineering the anode to minimize swelling and cracking, two challenges that previously limited silicon’s use in batteries.

Benefits of Silicon Anode Batteries:

-

Increases driving range significantly

-

Enables faster charging times

-

Enhances battery durability

-

Compatible with existing manufacturing setups

As these batteries enter commercial production, they are expected to revolutionize the mid- and high-end EV segments in the U.S.

3. Lithium Iron Phosphate (LFP) Batteries: Affordable and Safe

While solid-state and silicon technologies target high-performance EVs, Lithium Iron Phosphate (LFP) batteries have gained popularity for being cost-effective, durable, and thermally stable.

Originally developed in China, LFP batteries are now being heavily produced in the United States. Tesla has begun incorporating LFP cells into its Model 3 and Model Y vehicles. American automakers appreciate that LFP cells contain no nickel or cobalt, reducing dependence on rare materials and lowering costs.

Advantages of LFP Batteries:

-

Longer cycle life (over 3,000 charge cycles)

-

Enhanced thermal stability (safer against overheating)

-

Lower production cost

-

Better recyclability

| Automaker | Battery Type | Key Feature |

|---|---|---|

| Tesla | LFP | Affordable and long-lasting |

| Ford | LFP | Uses U.S.-based battery plant with CATL collaboration |

| Rivian | LFP (in development) | Aims to reduce vehicle cost |

These batteries are making EV ownership more accessible to the general public.

4. Fast-Charging and Ultra-High-Power Batteries

Charging time has long been a barrier for EV adoption. Recent U.S. research has produced batteries that can charge five times faster, even in cold weather.

Scientists at the University of Michigan and Pennsylvania State University have developed new electrode designs and thermal management systems allowing lithium-ion batteries to charge rapidly without overheating. These technologies could enable EVs to achieve 300 miles of range in just 10 minutes of charging.

In parallel, companies like StoreDot and Enovix are developing Extreme Fast Charging (XFC) cells. These breakthroughs focus on controlling ion flow more efficiently to prevent degradation during rapid charging.

Benefits:

-

Reduces charging time drastically

-

Improves convenience and practicality

-

Encourages EV adoption in colder U.S. regions

5. Next-Generation Battery Chemistries: Beyond Lithium

While lithium remains dominant, U.S. scientists are exploring alternative chemistries to reduce costs and supply chain dependency.

Sodium-Ion Batteries

Sodium-ion batteries are gaining attention as they use abundant sodium instead of lithium. Research by Natron Energy and Pacific Northwest National Laboratory (PNNL) focuses on improving energy density and efficiency for EV applications.

Lithium-Sulfur Batteries

Lithium-sulfur batteries can store two to three times more energy than lithium-ion, using cheaper and more sustainable materials. Startups like Lyten and Oxis Energy USA are testing prototypes for automotive use.

| Chemistry Type | Key Materials | Advantages | Challenges |

|---|---|---|---|

| Sodium-Ion | Sodium, Iron | Low cost, abundant materials | Lower energy density |

| Lithium-Sulfur | Sulfur, Lithium | Very high energy potential | Cycle stability issues |

| Magnesium-Ion | Magnesium | Non-flammable, safe | Limited scalability |

Such alternatives could secure America’s long-term energy independence and sustainability goals.

6. Battery Recycling and Circular Economy

As EV adoption grows, managing end-of-life batteries becomes a crucial challenge. U.S. innovators are creating closed-loop recycling systems to extract valuable materials like lithium, nickel, and cobalt for reuse.

Redwood Materials, founded by Tesla co-founder JB Straubel, is a leader in EV battery recycling. The company processes old batteries to recover up to 95% of key elements and reintroduces them into the supply chain.

Other notable initiatives include:

-

Li-Cycle (New York): Uses hydrometallurgical processes for safer recycling.

-

American Battery Technology Company (ABTC): Focuses on domestic raw material recovery.

-

Ascend Elements (Massachusetts): Develops “closed-loop” cathode manufacturing from recycled materials.

| Company | Focus Area | Recycled Material Recovery Rate |

|---|---|---|

| Redwood Materials | EV battery recycling | 95% |

| Li-Cycle | Battery waste processing | 90% |

| ABTC | Material recovery | 85% |

Recycling not only reduces environmental impact but also lowers costs for automakers and consumers.

7. AI-Driven Battery Management Systems (BMS)

Artificial Intelligence (AI) is playing a critical role in optimizing battery health and performance. AI-powered Battery Management Systems are being developed to predict degradation, monitor temperature, and balance energy flow across cells.

Companies like Twaice, Nuvve, and Clarios are working with U.S. automakers to integrate predictive analytics into battery systems. These smart systems ensure safety, improve energy efficiency, and extend battery lifespan.

AI also helps detect anomalies early, preventing issues like thermal runaway or uneven cell aging. As a result, vehicles become safer and more reliable for long-term use.

8. Battery Manufacturing Expansion in the USA

To support these innovations, the United States is rapidly expanding domestic battery production. Federal policies under the Inflation Reduction Act (IRA) and Bipartisan Infrastructure Law have allocated billions to support new gigafactories and local supply chains.

Major manufacturing developments include:

-

GM’s Ultium Cells facilities in Ohio and Tennessee.

-

Ford’s BlueOval Battery Park in Kentucky.

-

Panasonic and Tesla’s Gigafactory Nevada expansion.

-

SK On and Hyundai’s battery plants in Georgia.

| Manufacturer | Location | Capacity (GWh/year) | Operational Year |

|---|---|---|---|

| GM Ultium Cells | Ohio, TN | 80 | 2025 |

| Ford BlueOval | Kentucky | 50 | 2026 |

| Panasonic | Nevada | 40 | 2025 |

| SK On | Georgia | 35 | 2026 |

This domestic scaling ensures a stable supply chain, reduces import dependency, and generates thousands of U.S. manufacturing jobs.

9. Sustainable Materials and “Forever-Chemical-Free” Batteries

Environmental safety remains at the forefront of innovation. U.S. researchers are eliminating harmful PFAS (“forever chemicals”) from EV battery components. Scientists at the University of Chicago have introduced new electrolyte compositions that maintain performance while avoiding toxic compounds.

Other sustainability efforts include:

-

Using bio-based binders instead of synthetic polymers.

-

Sourcing lithium from geothermal brine in California’s Salton Sea region.

-

Promoting ethical mining and local material sourcing.

These eco-friendly practices align with the nation’s broader commitment to clean energy and sustainable production.

10. Grid Storage and Second-Life Applications

As EV batteries age, they often retain up to 80% capacity — making them ideal for second-life uses such as energy storage for homes or renewable grids.

Companies like B2U Storage Solutions and Nissan Energy are leading second-life battery projects in the U.S., creating storage systems that stabilize renewable energy output and reduce waste.

| Application | Description | Example Project |

|---|---|---|

| Home Energy Storage | Repurposed EV batteries for residential backup | Nissan LEAF Energy Home System |

| Grid Storage | Supports renewable energy grids | B2U Solar + Storage Plant in California |

| EV Charging Stations | Stores energy for peak demand periods | Tesla Powerpack Integration |

This circular approach extends the life of batteries and reduces the carbon footprint of the EV industry.

Economic and Environmental Impact of EV Battery Innovation

The rapid development of battery technology is transforming both the U.S. economy and its environmental landscape. Some key impacts include:

-

Economic Growth: The EV battery industry is projected to create over 300,000 new jobs by 2030.

-

Energy Independence: Domestic production reduces reliance on foreign suppliers for critical materials.

-

Emission Reduction: Every EV powered by advanced batteries helps reduce greenhouse gas emissions by up to 70% compared to gasoline vehicles.

-

Waste Reduction: Improved recycling and second-life systems minimize environmental pollution.

The synergy between innovation, investment, and policy is building a robust clean-energy ecosystem.

Conclusion

The United States is at the forefront of a global race to revolutionize EV battery technology. Through the combined efforts of universities, startups, and major automakers, new generations of batteries are emerging that promise longer range, faster charging, lower cost, and greater sustainability.

From solid-state breakthroughs to circular recycling systems, EV battery innovations in the USA are reshaping not only the automotive industry but also the country’s energy and environmental landscape. As research continues and production scales up, these innovations will help make electric mobility the new normal — clean, efficient, and accessible for all Americans.

2 thoughts on “EV Battery Innovations in USA: Powering the Future of Sustainable Mobility”